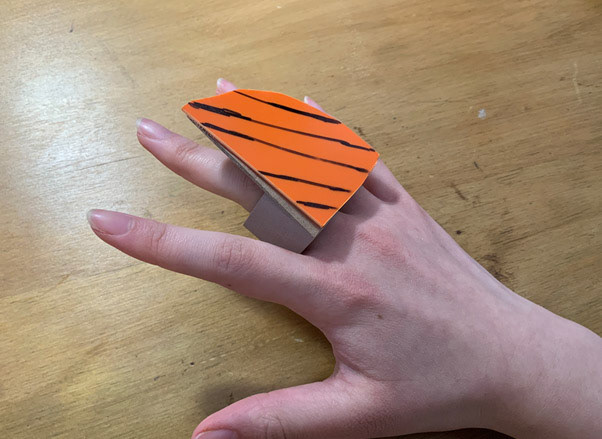

This was a project that was done as a group of 3, where we designed and made a functioning wearable bike light that worked as an indicator for turning. With an internal gyroscope, the glove could sense the angle at which it was rotated and after a certain point (40*) the indicator would activate and then begin flashing the High Power LED.

To begin our prototyping stage we could not decide simply on sketches so we decided to split ways and create our ideal design and then reconvene and discuss again which design we would take forward. After this, we unanimously decided on the glove design as it seemed the most sensible, and many cyclists already wear gloves to cycle so it would not be a particularly odd concept to understand. From there we progressed into CAD and rapid prototyping iteration of this design and rather than spend time and money on excessive physical tests we decided to use FEA.

Pictured above are some examples of our FEA testing, this is what allowed us to change the CAD designs and then apply forces to these components in a way that would mimic the normal forces these pieces would experience, like this clip that would be pressed against with some force for something so small, so the design needed to be reinforced for longevity and reliability.

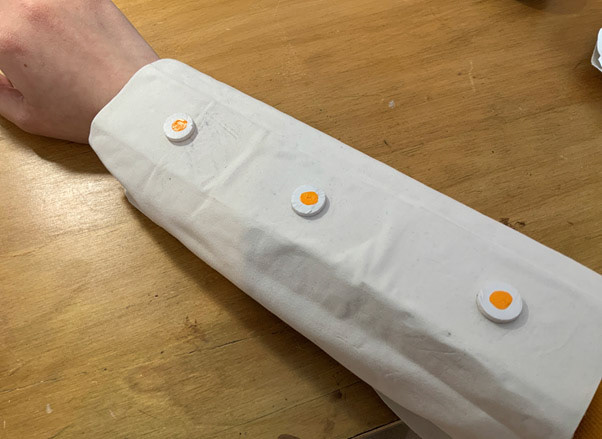

After all these iterations we had a fully functioning prototype and design, with properly nested and working components simply and easily to access allowing the user to change and check the batteries with ease.